Home » Scientific%20research%20progress

Metal-organic frameworks and their derived materials for electrochemical energy storage and conversion: Promises and challenges

Science Advances 01 Dec 2017:

Vol. 3, no. 12, eaap9252

DOI: 10.1126/sciadv.aap9252

Introduction to MOF

Metal-Organic Frameworks (MOFs) are organic-inorganic hybrid materials with intramolecular pores formed by self-assembly of organic ligands and metal ions or clusters by coordination bonds. MOFs have some attractive characteristics, such as large specific surface area, highly ordered pores, adjustable size structure and composition and ease to be functionalized. Such structural features make it have broad application prospects in gas adsorption and separation, heterogeneous catalysis, chemical detection, biomedicine and other fields. Due to the organic-inorganic hybrid characteristics, porous structure and reaction characteristics, MOFs can be used as precursors for the controlled synthesis of various inorganic functional materials with micro/nano structures. Metal-organic frameworks and their derivatives have received extensive attention in recent years, especially in the field of energy storage.

Research output

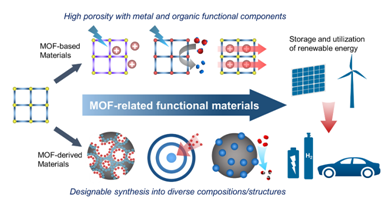

Research Professor Haobin Wu from Zhejiang University and Professor Xiongwen Lou from Nanyang Technological University in Singapore published a review article about emerging applications of pristine MOF-based materials and MOF-derived materials in fields of electrochemical energy storage and catalysis. (Wu and Lou, Sci. Adv. 2017;3: eaap9252) The paper reviewed the research status and application prospects of MOF-related materials in secondary batteries, electrochemical capacitors, electrolyzed water hydrogen production and fuel cells. On the one hand, MOF-related materials can be used as electrode materials for energy storage devices such as batteries and capacitors, as well as electrocatalysts for electrochemical energy conversion technologies such as electrochemical fuels and fuel cells. In addition, new solid electrolytes can also be developed by preparing MOFs with ionic conductivity. On the other hand, MOFs can be used as a precursor to prepare inorganic functional materials with different chemical compositions, micro-nanostructures and excellent electrochemical properties. Excellent electrochemical energy storage and catalytic performance can be realized through the regulation of components and structures. As a kind of emerging functional material, MOFs and their derivatives provide new opportunities for clean and efficient use of renewable energy, but related research also faces various challenges.

Fig. 1. Schematic of MOF-related materials for renewable energy.

Fig.

2. MOF-related materials for charge storage.

A-C.

A redox-active MOF for lithium batteries;

D.

Schematic of electrochemical Na storage in Prussian blue crystal;

E-F.

Electrochemical capacitor based on MOFs;

G-I.

Electronic conductive MOFs for electrochemical capacitors;

J-L.

MOFs as sulfur host for lithium-sulfur (Li-S) batteries.

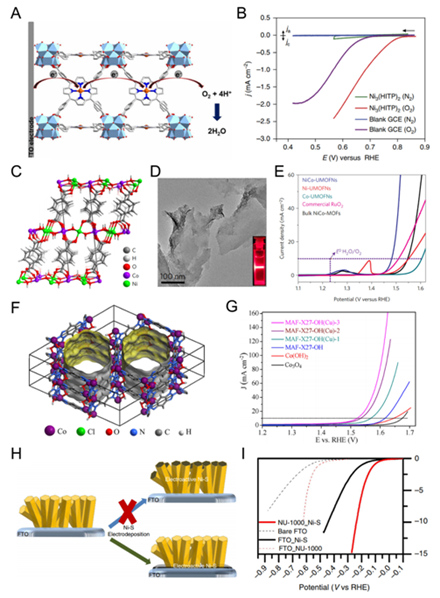

Fig.

3. MOF-related materials for electrocatalysis:

A-B. MOFs for redox reaction;

C-E. UMOFNs as an electrocatalyst for OER;

F-G. A Co-based MOF for OER:

H-I. MOFs-assisted electrochemical hydrogen production.

Fig. 4. MOF-related materials for ionic conduction:

A-C. MOFs with acid radicals as proton conductor;

D-E. MOFs adsorbing imidazole molecules as proton conductors;

F-G. MOFs-based proton conductors with layered structure and continuous hydrogen bonding;

H-I. MOFs-based lithium-ion conductor.

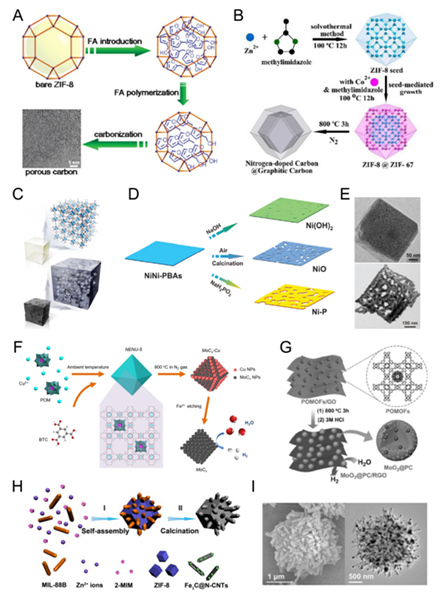

Fig. 5. Compositional control of MOF-derived materials:

A-C. Porous carbon material and composite material derived from MOFs;

D-E. A variety of nickel-based compounds derived from MOFs;

F-I. Molybdenum-carbon and iron carbide-carbon composites derived from MOF composite precursors.

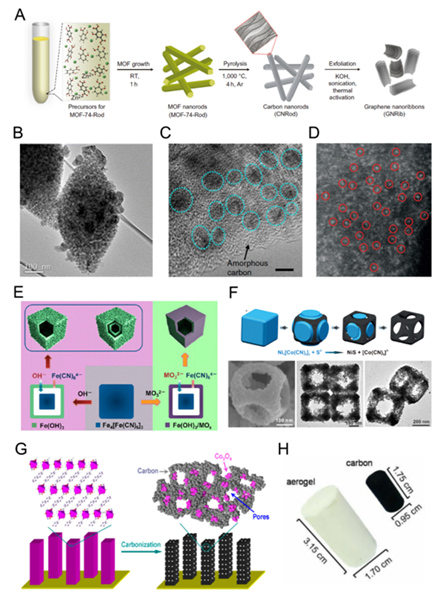

Fig. 6. Morphological and structural control of MOF-derived materials:

A. 1D and 2D nanocarbon materials derived from MOFs;

B-D. Porous carbon supported molybdenum carbide nanoparticle composite structure derived from MOFs;

E-F. Hollow and frame structures derived from MOFs;

G-H. Nanowire array and porous bulk structure derived from MOFs.

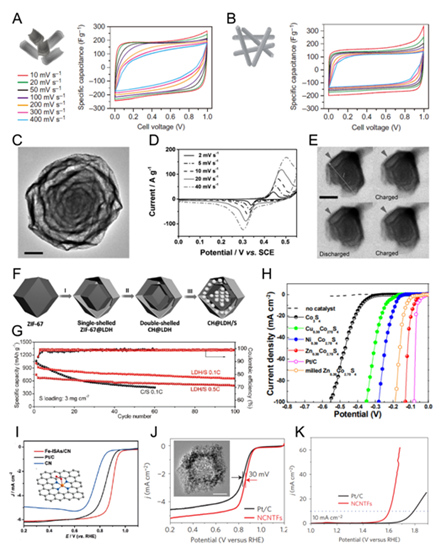

Fig. 7. Functionalities and applications of MOF-derived materials:

A-B. Nano carbon materials derived from MOFs for EDLC;

C-E. Multilayer hollow oxide derived from MOFs for hybrid capacitors;

F-G. Hollow structure derived from MOFs used as sulfur carrier for lithium sulfur battery;

H. Metal sulfides derived from MOFs for electrochemical hydrogen production;

I-K. Carbon nanotube hollow structure derived from MOFs as an oxygen reduction-oxygenation dual function catalyst.